Case Study: How Messer Helped Cincinnati Children’s Maximize Opportunities for Speed to Market, Prefabrication and Workforce Diversity

To continue providing the best medical/quality-of-life outcomes and patient/family experiences, Cincinnati Children’s needed a cost-effective, state-of-the-art critical care addition to support patients with the most critical of needs and successful treatment. The innovative 650,000 sf Critical Care Building was delivered on time and on budget through a collaborative approach to address Cincinnati Children's need for speed to market with efficiencies like prefabrication and Flow Scheduling, and a goal to build a diverse workforce, break the cycle of poverty and change the trajectory for families in the surrounding community.

See how Flow Scheduling works.

Go slow to get fast: a four-month schedule reduction

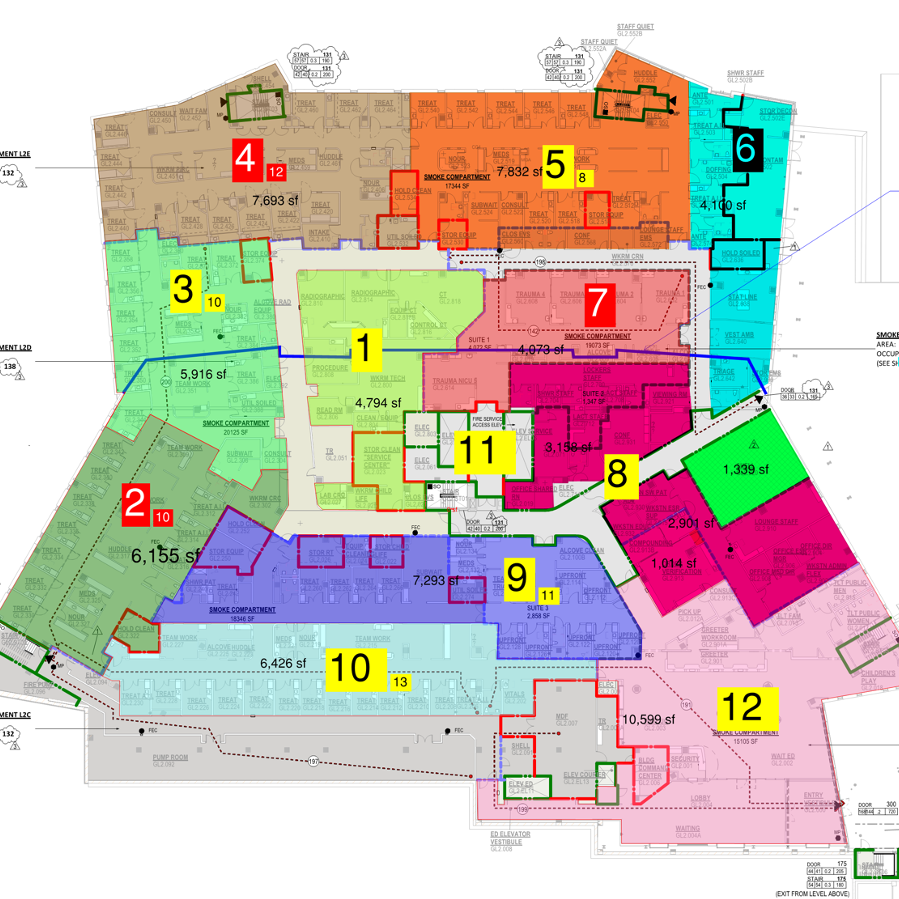

Flow Scheduling consists of grouping a construction project into similarly sized or dense areas (instead of an entire floor), determining the best sequence, and then setting a rhythm or takt time for completing the work. The result is a faster, more efficient completion of the project, better quality, earlier mock-ups, and a safer work environment for everyone. Flow allows for the concept of “go slow to get fast,” and we saw these results at the Critical Care Building:

- Enabled on-time completion for all key construction milestones

- Combined with prefabrication, Flow Scheduling enabled a four-month schedule reduction

Driving safety, schedule and quality with prefabrication

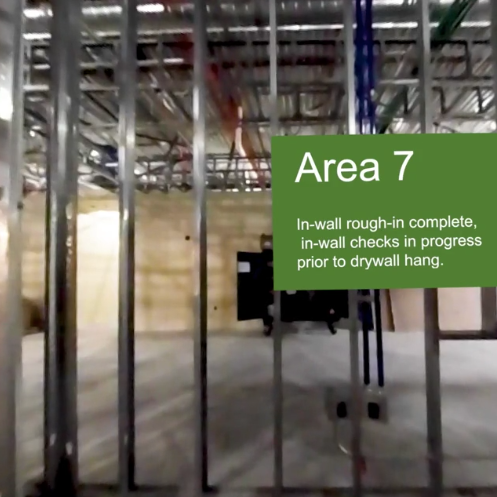

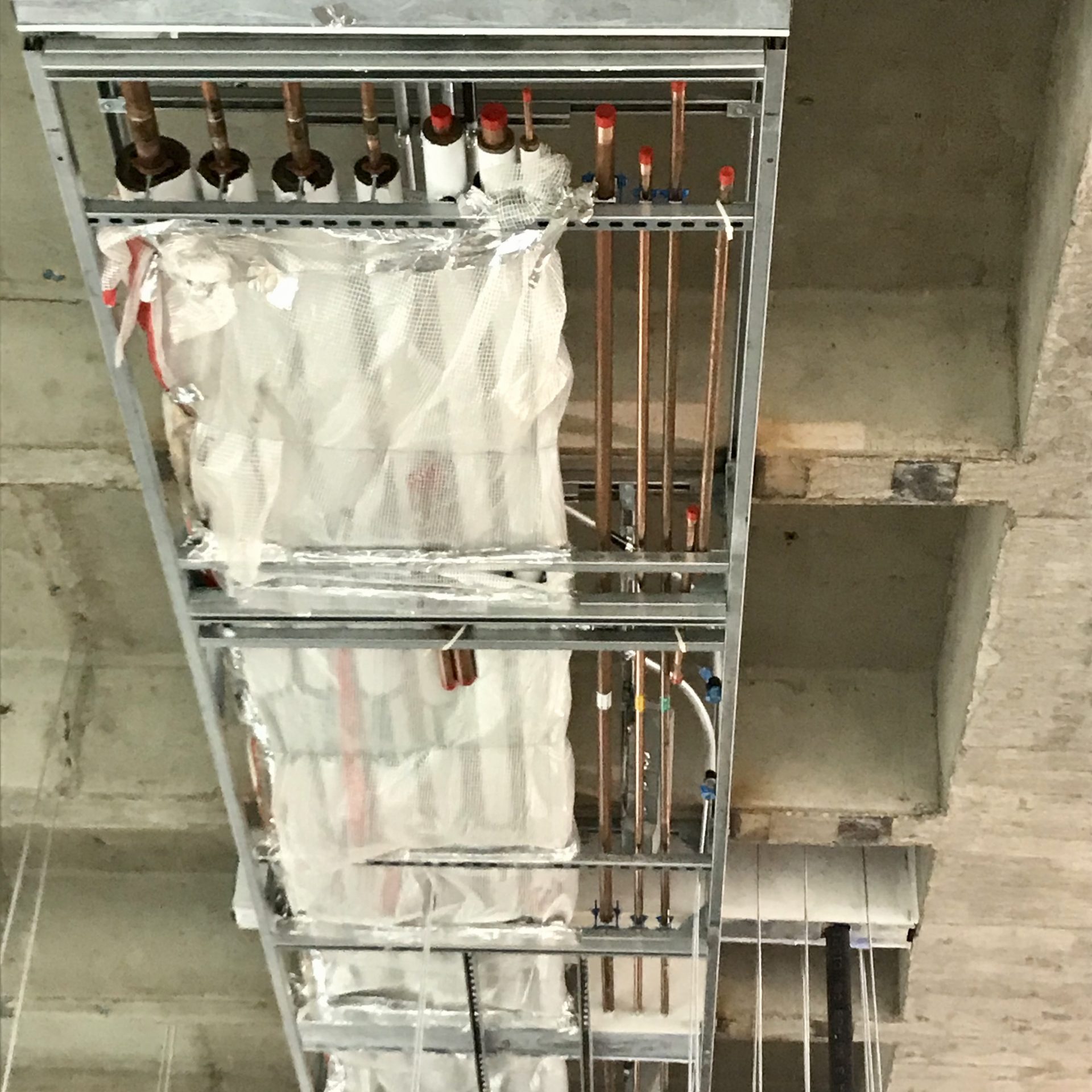

Prefabrication was critical to achieve the aggressive schedule goal. More than 50% of the project was completed using prefabrication and off-site construction, including the following components:

- Exterior wall panels

- Bathroom PODs

- MEP racks/MED gas racks

- Zone valve box assemblies

- Duct risers/pipe risers

- Casing panels

- Electrical room in-box rough-In

- Interior metal studs

- Unitized curtain wall system

- 110' connector bridge

The elements highlighted in this animation were prefabricated.

Building sustainable careers and workforce diversity

The focus on diversity, equity and inclusion, and the removal of systemic barriers, is of utmost importance. Meeting people where they are to build a pipeline of candidates requires bringing together partners focused on the same target: to get and keep individuals in sustainable careers.The original idea to make these two points happen began with Messer's partnership with Cincinnati Children’s and Easterseals Serving Greater Cincinnati’s Building Value program. Launched in 2017, Uptown Workforce Development Initiative (UWDI) focuses on Uptown neighborhoods in Greater Cincinnati, with the goal to bring 50 residents into full-time careers by the end of 2021. UWDI does this through paid training, social support, the promise of a full-time job upon completion and a strong career outlook.

- The initiative is on track to meet the goal, with 45 people employed as of October 2021

- Surpassed the on-the-job personnel goal of 25% with 27% success

We are bringing this workforce development model to scale and extending the initiative to other regions as an expanded version of UWDI – the Urban Workforce Development Initiative.

Strong results

- The four-year $600 million project was completed on time and on budget

- Surpassed the 30% M/WBE spending goal at 35%

- Added two minority partners to our CM team

- Learn more about the project

The Critical Care Building is a remarkable achievement

in the 138-year-history of Cincinnati Children's. This new facility, which is the largest expansion ever undertaken at Cincinnati Children's, is the result of a collaboration with our patients, families, staff, board, donors, and community. We are thankful to everyone who played a role."

Michael Fischer President and CEO, Cincinnati Children's